Pump Lift Stations 101 Webinar Recap

NWPX stands at the forefront of engineered water management solutions in North America, manufacturing innovative systems for water distribution, stormwater quality, and wastewater pretreatment. NWPX’s solutions serve municipalities, developers, engineers, and contractors nationwide, and our advanced Pump Lift Station technology forms the backbone of modern water and wastewater infrastructure. These systems help move fluids from low-lying areas, overcoming topographical constraints in commercial, industrial, and residential environments. Our recent Pump Lift Stations 101: Design, Applications, and Real-World Examples webinar provided attendees with a comprehensive look at lift station fundamentals, design best practices, and project-ready solutions for smarter, more reliable systems.

The Role of Packaged Lift Stations in Infrastructure

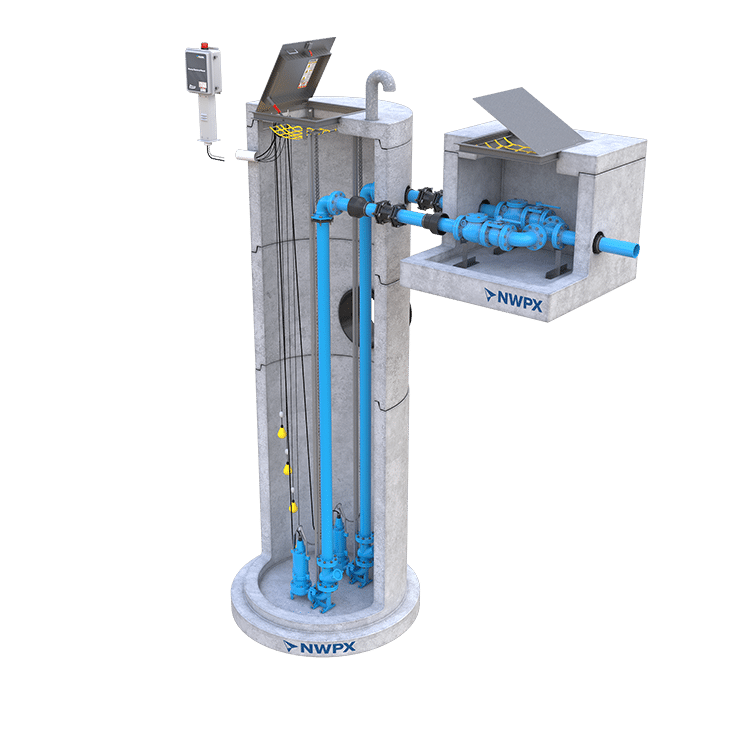

Packaged lift stations are pre-engineered to simplify installation, boost reliability, and meet the unique needs of every project. NWPX delivers fully assembled and factory-tested systems that arrive at the jobsite ready for connection, reducing labor and avoiding common site complications. Essential offerings include:

- Stormwater pump stations for flood prevention.

- Sanitary sewer lift stations tailored to residential, commercial, and industrial sites.

- Robust structures for complex projects such as detention ponds, hospitals, schools, and prisons.

The Role of Packaged Lift Stations in InfrastInside the Technology: Key Components and Controls

Optimal lift station design demands proper wet well sizing and informed selection of pumps, valves, and control systems. NWPX’s solutions include:

- Submersible centrifugal pumps for quiet, efficient operation and motor cooling.

- Grinder and chopper pumps for high-use facilities like schools, prisons, and medical centers, helping to minimize clogs and maintenance.

- Non-clog pumps engineered for hazardous, high-flow environments.

Pump stations feature guide rails and stainless steel lifting chains for safe maintenance, robust access hatches, advanced venting systems, and corrosion-resistant HDPE liners with a 50-year guarantee. Sophisticated control panels support efficient lead-lag operation, failover redundancy, and seamless integration with IoT monitoring for real-time alerts and remote management.

Design Fundamentals: Planning for Peak Performance

Building a high-performance, resilient pump lift station starts with accurate flow calculations and smart site selection. NWPX’s proven methods ensure:

- Properly sized pumps to serve peak flow rates, using multipliers for daily averages by population or facility.

- Wet wells sized to prevent short cycling and overheating, with the right float and alarm settings.

- Total dynamic head calculated by combining elevation differences and friction losses to select pumps with the best efficiency curves.

- Flexible duplex, triplex, or quadplex configurations for maximum reliability.

Elevate Your Water Infrastructure with NWPX

The Pump Lift Stations 101 webinar demonstrated how NWPX’s expertise solves real-world water infrastructure challenges, from initial flow calculations to specialized pump selection, advanced controls, and durable accessories. Every step is meticulously streamlined so stakeholders save time, minimize risks, and achieve installations built to last. With factory-assembled quality and unmatched project support, NWPX ensures every lift station performs at its best for years to come.